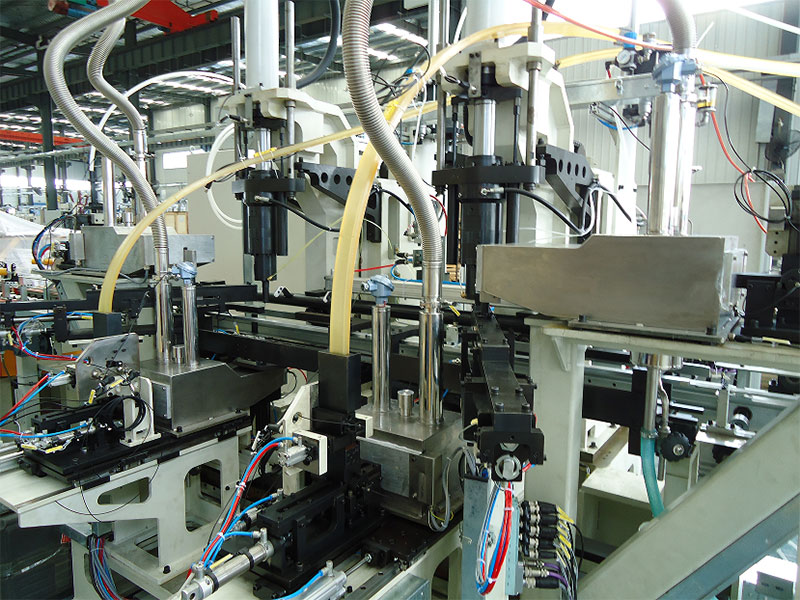

Foromo/tanka ea naetrojene e metsi, e nang le vacuum e sa tieang (e Matla)()E tenyetseha)Mekhoa ea Liphaephe, Li-valve tse Sirelelitsoeng ka Vacuum le Li-Apartament tsa Mokhahlelo oa Vacuum lia hlokahala bakeng sa kopano ea cryogenic ea enjene ea koloi. Kopano ea cryogenic ea likarolo tsa enjene ea koloi e na le melemo e mengata eo e ka bapisoang le ts'ebetso ea kopano ea setso. Hona joale e se e sebelisoa haholo lienjeneng tsa likoloi le lifemeng tsa tlhahiso ea lienjene tsa motlakase.

Sesebelisoa sa HL Cryogenic Equipment se na le boiphihlelo ba lilemo tse 15 indastering ea enjine ea likoloi le indasteri ea li-electromotor. Se bokelletse boiphihlelo le tsebo e ngata, ka bokhoni ba ho "sibolla mathata a bareki", "ho rarolla mathata a bareki" le "ho ntlafatsa litsamaiso tsa bareki".

Kopano ea cryogenic e na le melemo e mengata ho feta kopano ea setso ea ho futhumatsa. Kopanong ea setso ea ho futhumatsa, likarolo li boemong bo sa tsitsang nakong ea ts'ebetso ea ho futhumatsa le ts'ebetso ea kopano tlas'a boemo ba mocheso o phahameng. Kamora ho khutlela mochesong o tloaelehileng le ts'ebelisong ea hamorao, ho ka etsahala hore ho be le phetoho e kholo.

Mathata a tloaelehileng a Sistimi ea Liphaephe tse Kenngoeng ka Vacuum kopanong ea cryogenic a kenyelletsa,

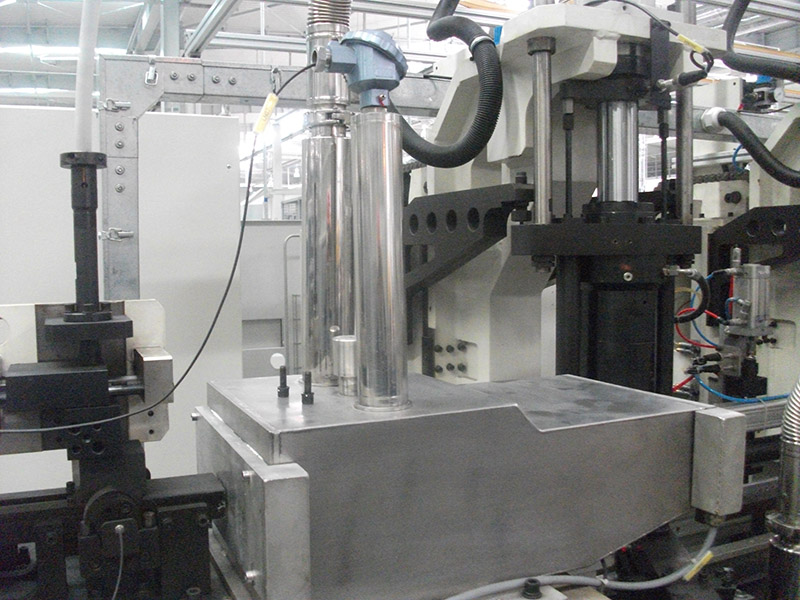

- Moralo o ikhethileng bakeng sa flume/tanka ea naetrojene e metsi eo e leng karolo ea bohlokoa le e ikhethang e leng motheo oa ts'ebetso ea ho pholisa ea kopano eohle ea enjene e nang le cryogenic.

- Nako ea ho Pholisa le Mekhoa ea Taolo e Iketsang ea likarolo tsa enjene ea Likoloi

- Mocheso oa Naetrojene e Metsi ka har'a Lisebelisoa tsa Terminal

- (Ka boiketsetso) Ho Fetola Mela e Meholo le ea Lekala

- Phetoho ea Khatello (Phokotso) le Botsitso ba VIP

- Ho Hloekisa Litšila Tse ka Bang Teng le Masalla a Leqhoa a tsoang Tankeng

- Ho Pholisa Liphaephe Pele ho Nako

- Khanyetso ea Metsi Tsamaisong ea VIP

Pipe ea HL e nang le Vacuum Insulated (VIP) e hahiloe ho latela khoutu ea ASME B31.3 Pressure Piping e le tekanyetso. Phihlelo ea boenjiniere le bokhoni ba taolo ea boleng ho netefatsa katleho le katleho ea fektheri ea moreki.

Lihlahisoa tse Amanang

BAREKI BA TUMILENG

- Volkswagen

- Comau

- Hyundai

- Koloi ea Dongfeng

LITHAROLLO

Sesebelisoa sa HL Cryogenic se fa bareki Sistimi ea Liphaephe tse Kenngoeng ka Vacuum ho fihlela litlhoko le maemo a Indasteri ea Enjene ea Likoloi le ea Electromotor:

1. Sistimi ea Tsamaiso ea Boleng: Khoutu ea Liphaephe tsa Khatello ea ASME B31.3.

2. Ho ya ka nako ya ho hoama ya mosebedisi le motsamao wa sesebelisoa sa ho laola, moralo o loketseng o a etswa.

3. Moralo o utloahalang le ho beoa ha Phase Separator ho Sistimi ea VI ea Liphaephe ke senotlolo sa ho netefatsa botsitso le khotsofalo ea khatello ea metsi le mocheso.

4. Letoto la Valve e Sirelelitsoeng ea Vacuum (VIV) le Fumanehang: Ho kenyeletsoa Valve e Sirelelitsoeng ea Vacuum (Pneumatic), Valve ea ho Check Insulated ea Vacuum, Valve e Laolang ea Vacuum jj. Mefuta e fapaneng ea VIV e ka kopanngoa ka mokhoa o ikhethileng ho laola VIP ha ho hlokahala. VIV e kopantsoe le VIP e entsoeng esale pele ho moetsi, ntle le kalafo ea Insulated sebakeng seo. Yuniti ea tiiso ea VIV e ka nkeloa sebaka habonolo. (HL e amohela letšoao la valve ea cryogenic le khethiloeng ke bareki, ebe e etsa li-valve tse sirelelitsoeng tsa vacuum ke HL. Mefuta e meng ea li-valve le mehlala ea li-valve e kanna ea se khone ho etsoa li-valve tse sirelelitsoeng tsa vacuum.)

5. Bohloeki, haeba ho na le litlhoko tse ling bakeng sa bohloeki ba bokaholimo ba tube ea ka hare. Ho khothalletsoa hore bareki ba khethe liphaephe tsa tšepe e sa ruseng tsa BA kapa EP e le liphaephe tsa ka hare tsa VIP ho fokotsa ho tšoloha ha tšepe e sa ruseng.

6. Sefe e Sirelelitsoeng ka Vacuum: Hloekisa litšila tse ka bang teng le masalla a leqhoa ka tankeng.

7. Kamora matsatsi a 'maloa kapa ho koaloa kapa tlhokomelo ho feta, ho hlokahala haholo ho pholile pele ho kenngoa mokelikeli oa cryogenic oa VI Piping le thepa ea terminal, e le ho qoba ho bola ha leqhoa kamora hore mokelikeli oa cryogenic o kene ka ho toba ho VI Piping le thepa ea terminal. Mosebetsi oa pele ho pholile o lokela ho nahanoa moralong. E fana ka tšireletso e betere bakeng sa lisebelisoa tsa terminal le lisebelisoa tsa tšehetso tsa VI Piping tse kang li-valve.

8. Se loketse Sistimi ea Liphaephe e Feto-fetohang le e sa Fetoheng ea Vacuum Insulated (e Tenyetsehang).

9. Sistimi ea Liphaephe tse Insulated ka Vacuum e Matla (e Tenyetsehang): E na le Liphaephe tse Fetohang tsa VI le/kapa Phaephe ea VI, Liphaephe tsa Jumper, Sistimi ea Valve e Insulated ka Vacuum, Li-Phase Separators le Sistimi ea Liphaephe tse Fetohang ka Vacuum (ho kenyeletsoa lipompo tsa vacuum, li-valve tsa solenoid le li-gauge tsa vacuum jj.). Bolelele ba Phaephe e le 'ngoe e Fetohang ea VI bo ka fetoloa ho latela litlhoko tsa mosebelisi.

10. Mefuta e fapaneng ea Khokahano: Mofuta oa Khokahano ea Vacuum Bayonet (VBC) le Khokahano e Welded li ka khethoa. Mofuta oa VBC ha o hloke kalafo e sireletsang sebakeng seo.