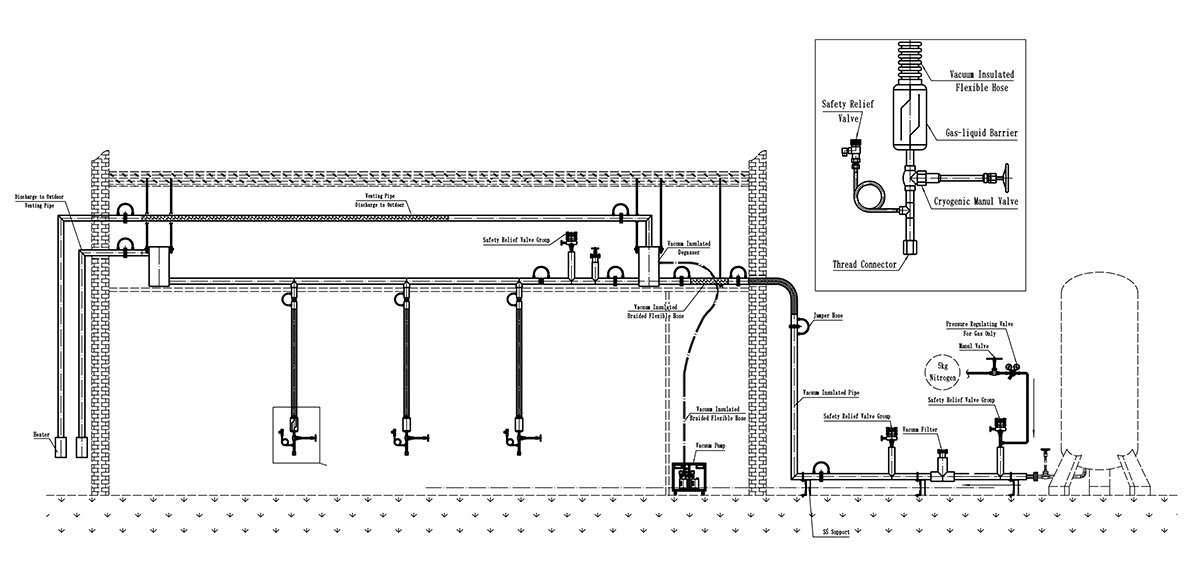

Tlhahiso le moralo oa Sistimi ea Liphaephe tse Sirelelitsoeng ka Vacuum bakeng sa ho tsamaisa naetrojene e metsi ke boikarabello ba mofani oa thepa. Bakeng sa projeke ena, haeba mofani a se na maemo a ho lekanya sebakeng seo, litšoantšo tsa tataiso ea phaephe li lokela ho fanoa ke ntlo. Ebe mofani oa thepa o tla rala Sistimi ea Liphaephe ea VI bakeng sa maemo a naetrojene e metsi.

Mofepedi o tla phethela moralo o akaretsang oa sistimi ea liphaephe ke baqapi ba nang le boiphihlelo ho latela litšoantšo, liparamente tsa lisebelisoa, maemo a sebaka, litšobotsi tsa naetrojene e metsi le lintlha tse ling tse fanoeng ke mokopi.

Dikahare tsa moralo di kenyeletsa mofuta wa disebediswa tsa sistimi, ho fumana thepa le ditlhaloso tsa diphaephe tsa kahare le kantle, moralo wa moralo wa ho kenya mocheso, moralo wa karolo e seng e hlophisitswe esale pele, foromo ya kgokelo pakeng tsa dikarolo tsa phaephe, bracket ya phaephe ya kahare, palo le sebaka sa vacuum valve, ho tloswa ha sekwahelo sa kgase, ditlhoko tsa mokelikeli wa cryogenic wa sesebediswa sa terminal, jj. Morero ona o lokela ho netefatswa ke basebetsi ba profeshenale ba morekisi pele o etswa.

Dikahare tsa moralo wa Sistimi ya Diphaephe tse Kentsweng ka Vacuum di pharaletse, mona ho dikopo tsa HASS le disebediswa tsa MBE mathateng a mang a tlwaelehileng, moqoqo o bonolo.

VI Liphaephe

Tanka ea polokelo ea naetrojene e metsi hangata e telele ho tloha ho lisebelisoa tsa HASS Application kapa MBE. Leha phaephe e koahetsoeng ka vacuum e kena ka hare ho moaho, e hloka ho qojoa ka ho utloahalang ho latela sebopeho sa kamore mohahong le sebaka sa phaephe ea tšimo le mothapo oa moea. Ka hona, ho tsamaisa naetrojene e metsi ho ea lisebelisoa, bonyane limithara tse makholo tsa phaephe.

Ka lebaka la hore naetrojene e metsi e hatelletsoeng ka boyona e na le khase e ngata, hammoho le sebaka sa lipalangoang, esita le phaephe e se nang letho ea adiabatic e tla hlahisa naetrojene e ngata ts'ebetsong ea lipalangoang. Haeba naetrojene e sa ntšoe kapa mosi o le tlase haholo ho fihlela litlhoko, e tla baka khanyetso ea khase mme e lebise phallong e mpe ea naetrojene e metsi, e leng se fellang ka phokotso e kholo ea sekhahla sa phallo.

Haeba sekgahla sa phallo se sa lekana, mocheso o ka phapusing ya naetrojene e metsi ya sesebediswa o ke ke wa laolwa, e leng se ka qetellang se lebisitse tshenyong ya sesebediswa kapa boleng ba sehlahiswa.

Ka hona, hoa hlokahala ho bala bongata ba naetrojene e metsi e sebelisoang ke lisebelisoa tsa terminal (HASS Application kapa MBE equipment). Ka nako e ts'oanang, litlhaloso tsa liphaephe li khethoa ho latela bolelele le tataiso ea liphaephe, hape.

Ho qala ka tanka ea polokelo ea naetrojene e metsi, haeba phaephe e kholo ea phaephe/hose e koahetsoeng ka vacuum e le DN50 (bophara ba kahare φ50 mm), phaephe/hose ea lekala la eona la VI ke DN25 (bophara ba kahare φ25 mm), 'me phaephe e pakeng tsa phaephe ea lekala le lisebelisoa tsa terminal ke DN15 (bophara ba kahare φ15 mm). Lisebelisoa tse ling bakeng sa sistimi ea liphaephe tsa VI, ho kenyeletsoa Phase Separator, Degasser, Automatic Gas Vent, VI/Cryogenic (Pneumatic) Shut-off Valve, VI Pneumatic Flow Regulating Valve, VI/Cryogenic Check Valve, VI filter, Safety Relief Valve, Purge system, le Vacuum Pump jj.

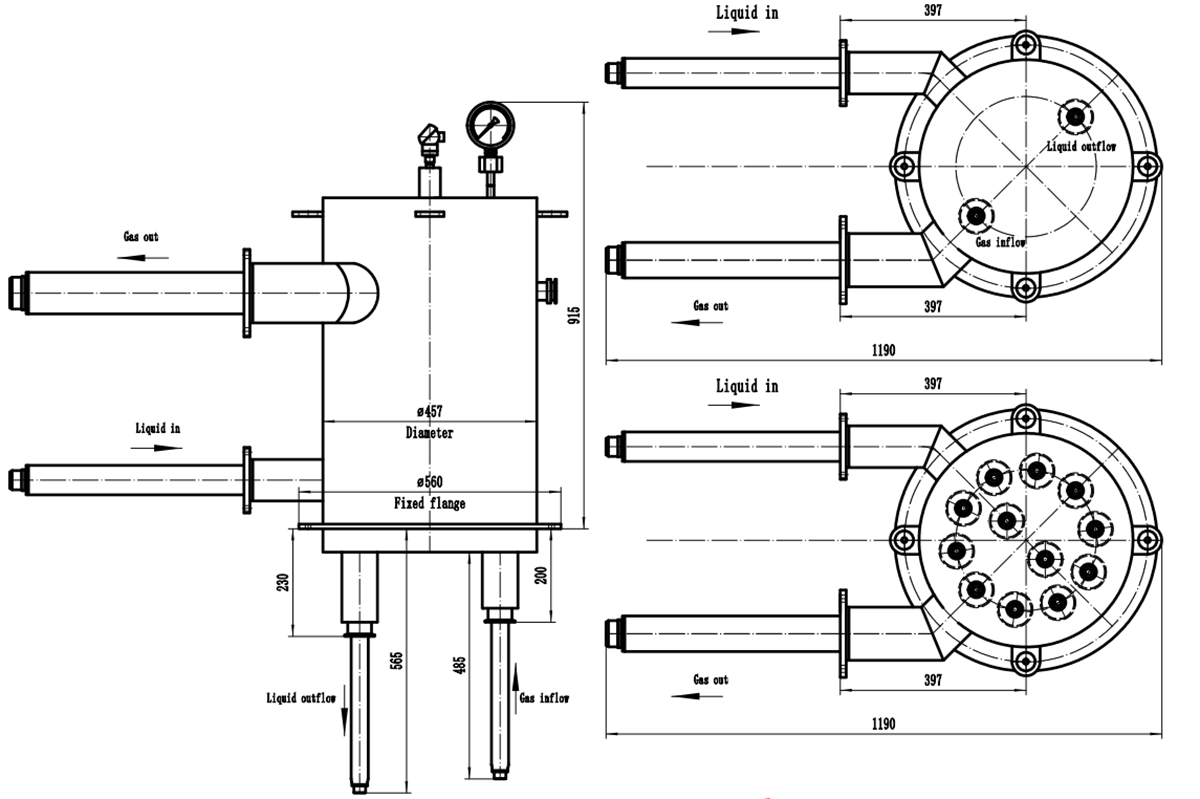

Sekarohano sa Mokhahlelo o Ikhethileng oa MBE

Karolo e 'ngoe le e 'ngoe e khethehileng ea karohano ea khatello e tloaelehileng ea MBE e na le mesebetsi e latelang:

1. Sensor ea boemo ba metsi le sistimi ea taolo ea boemo ba metsi e iketsang, 'me e bontšoa ka potlako ka lebokoseng la taolo ea motlakase.

2. Mosebetsi oa ho fokotsa khatello: ho kenella ha metsi ha karohano ho na le sistimi e thusang ea karohano, e netefatsang khatello ea naetrojene ea metsi ea li-bar tse 3-4 phaepheng e kholo. Ha u kena ho Phase Separator, fokotsa khatello butle-butle ho ≤ 1Bar.

3. Taolo ea phallo ea metsi a kenang: sistimi ea taolo ea ho phaphamala e hlophisitsoe ka hare ho Phase Separator. Mosebetsi oa eona ke ho fetola ka bohona bongata ba metsi a kenang ha tšebeliso ea naetrojene ea metsi e eketseha kapa e fokotseha. Sena se na le molemo oa ho fokotsa ho feto-fetoha ho matla ha khatello ho bakoang ke ho kena ha naetrojene e ngata ea metsi ha valve ea pneumatic ea metsi a kenang e buloa le ho thibela khatello e feteletseng.

4. Mosebetsi oa buffer, bophahamo ba modumo bo sebetsang ka hare ho karohano bo tiisa phallo e phahameng ka ho fetisisa ea hang-hang ea sesebelisoa.

5. Sistimi ea ho hloekisa: phallo ea moea le mouoane oa metsi ka har'a karohano pele ho phallo ea naetrojene e metsi, le ho ntšoa ha naetrojene e metsi ka har'a karohano kamora phallo ea naetrojene e metsi.

6. Mosebetsi oa ho imolla khatello e feteletseng ka boiketsetso: Lisebelisoa, ha li qala ho feta ka har'a naetrojene e metsi kapa tlas'a maemo a ikhethang, li lebisa keketsehong ea khase ea naetrojene e metsi, e leng se lebisang khatellong e phahameng ea sistimi eohle hang-hang. Sekhaohano sa rona sa Mokhahlelo se na le Valve ea Phomolo ea Polokeho le Sehlopha sa Valve ea Phomolo ea Polokeho, tse ka netefatsang botsitso ba khatello ka har'a karohano ka katleho le ho thibela lisebelisoa tsa MBE ho senyeha ke khatello e feteletseng.

7. Lebokose la taolo la motlakase, pontsho ya nako ya sebele ya boemo ba mokelikeli le boleng ba kgatello, le ka beha boemo ba mokelikeli ka hara karohano le naetrojene ya mokelikeli ho ya ka bongata ba kamano ya taolo. Ka nako e ts'oanang. Maemong a tshohanyetso, ho thijwa ha karohano ya mokelikeli wa kgase ka letsoho ka hara valve ya taolo ya mokelikeli, bakeng sa polokeho ya basebetsi le disebediswa sebakeng seo ho fana ka tiisetso.

Sesebelisoa sa ho hlakola metheo e mengata bakeng sa lits'ebetso tsa HASS

Tanka ea polokelo ea naetrojene e metsi e kantle e na le naetrojene e ngata hobane e bolokoa le ho tsamaisoa tlas'a khatello. Tsamaisong ena, sebaka sa ho tsamaisa liphaephe se selelele, ho na le litsoe tse ngata le khanyetso e kholoanyane, e leng se tla baka ho fetoha ha naetrojene e metsi ka karolo e itseng. Tube e koahetsoeng ka vacuum ke tsela e molemohali ea ho tsamaisa naetrojene e metsi hajoale, empa ho lutla ha mocheso ho ke ke ha qojoa, e leng se tla boela se lebise ho ho fetoha ha naetrojene e metsi ka karolo e itseng. Ha re akaretsa, naetrojene e metsi e na le naetrojene e ngata, e leng se lebisang tlhahisong ea khanyetso ea khase, e leng se etsang hore phallo ea naetrojene e metsi e se ke ea boreleli.

Lisebelisoa tsa ho ntša mosi tse holim'a phaephe e koahetsoeng ka vacuum, haeba ho se na sesebelisoa sa ho ntša mosi kapa bophahamo bo sa lekaneng ba mosi, li tla lebisa ho hanelong ea khase. Hang ha khanyetso ea khase e se e thehiloe, bokhoni ba ho tsamaisa naetrojene e metsi bo tla fokotseha haholo.

Sesebelisoa sa ho tlosa mokelikeli oa Multi-core se entsoeng ke k'hamphani ea rona feela se ka netefatsa hore naetrojene e ntšoa phaepheng e kholo ea naetrojene ea metsi ho isa tekanyong e phahameng ka ho fetisisa le ho thibela ho thehoa ha khanyetso ea khase. 'Me Sesebelisoa sa ho tlosa mokelikeli oa Multi-core se na le bophahamo bo lekaneng ba ka hare, se ka bapala karolo ea tanka ea polokelo ea buffer, 'me se ka fihlela litlhoko tsa phallo e phahameng ka ho fetisisa ea hang-hang ea phaephe ea tharollo.

Sebopeho se ikhethang sa metheo e mengata se nang le patente, bokgoni bo sebetsang ba ho ntsha mosi bo feta mefuta e meng ya di-aparthor.

Ha re tswela pele ka sengoloa se fetileng, ho na le dintlha tse ding tse hlokang ho nahanelwa ha ho ralwa ditharollo tsa Sistimi ya Diphaephe tse Kentsweng ka Vacuum bakeng sa ditshebediso tsa cryogenic Indastering ya Di-Chip.

Mefuta e 'Meli ea Sistimi ea Liphaephe tse Sirelelitsoeng ka Vacuum

Ho na le mefuta e 'meli ea Sistimi ea Liphaephe tse Sirelelitsoeng ka Vacuum: Sistimi ea Static VI le Sistimi ea Dynamic Vacuum Pumping.

Sistimi ea Static VI e bolela hore kamora hore phaephe e 'ngoe le e 'ngoe e etsoe fekthering, e hloekisoa ka vacuum ho fihlela tekanyo e boletsoeng ea vacuum yuniti ea ho pompa 'me e koetsoe. Ha e kenngoa tšimong 'me e sebelisoa, nako e itseng ha e hloke ho khutlisetsoa sebakeng seo.

Molemo oa Sistimi ea Static VI ke litšenyehelo tse tlase tsa tlhokomelo. Hang ha sistimi ea liphaephe e se e sebetsa, tlhokomelo e hlokahala lilemo tse 'maloa hamorao. Sistimi ena ea vacuum e loketse litsamaiso tse sa hlokeng litlhoko tse phahameng tsa ho pholisa le libaka tse bulehileng bakeng sa tlhokomelo sebakeng seo.

Bothata ba Sistimi ea Static VI ke hore vacuum cleaner e fokotseha ha nako e ntse e ea. Hobane thepa eohle e ntša likhase tse sa reng letho ka linako tsohle, e leng se khetholloang ke thepa ea 'mele ea thepa. Thepa e ka har'a baki ea VI Pipe e ka fokotsa bongata ba khase e lokolloang ke ts'ebetso, empa e ke ke ea aroloa ka botlalo. Sena se tla lebisa ho vacuum ea tikoloho ea vacuum e koetsoeng, e tla ba tlase le ho feta, tube ea ho thibela vacuum e tla fokolisa butle-butle bokhoni ba ho pholisa.

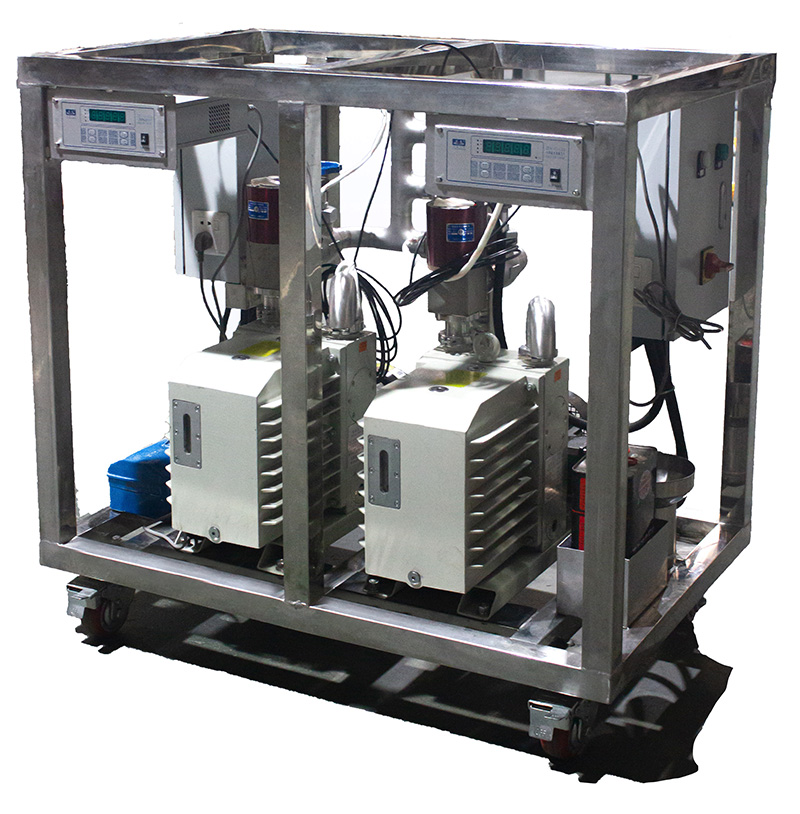

Sistimi ea ho Pompa ka Vacuum e Matla e bolela hore ka mor'a hore phaephe e etsoe le ho etsoa, phaephe e ntse e ntšoa fekthering ho latela mokhoa oa ho lemoha ho lutla ha metsi, empa vacuum ha e koetsoe pele e tlisoa. Kamora hore ho kenngoe tšimo ho phethoe, likarolo tsa vacuum tsa liphaephe tsohle li tla hokeloa ho yuniti e le 'ngoe kapa tse ngata ka liphaephe tsa tšepe e sa hloekang, 'me pompo e nyane e inehetseng ea vacuum e tla sebelisoa ho hloekisa liphaephe tse tšimong. Pompo e khethehileng ea vacuum e na le sistimi e iketsang ea ho lekola vacuum neng kapa neng, le vacuum ha ho hlokahala. Sistimi e sebetsa lihora tse 24 ka letsatsi.

Bothata ba Sistimi ea ho Pompa ka Vacuum e Matla ke hore vacuum e hloka ho hlokomeloa ke motlakase.

Molemo oa Sistimi ea ho Pompa ka Vacuum e Matla ke hore tekanyo ea vacuum e tsitsitse haholo. E sebelisoa haholo tikolohong ea ka tlung le litlhoko tsa ts'ebetso ea vacuum ea merero e phahameng haholo.

Sistimi ea rona ea ho Pompa ka Vacuum e Matla, pompo eohle e ikhethileng ea vacuum e kopantsoeng e tsamaeang ho netefatsa hore lisebelisoa lia hloeka, sebopeho se bonolo le se utloahalang ho netefatsa phello ea vacuum, boleng ba lisebelisoa tsa vacuum ho netefatsa boleng ba vacuum.

Bakeng sa projeke ea MBE, hobane lisebelisoa li ka phapusing e hloekileng, 'me lisebelisoa li sebetsa nako e telele. Bongata ba sistimi ea liphaephe tse koahetsoeng ka vacuum e sebakeng se koetsoeng holim'a lera la kamore e hloekileng. Ho ke ke ha khoneha ho kenya tšebetsong tlhokomelo ea vacuum ea sistimi ea liphaephe nakong e tlang. Sena se tla ba le tšusumetso e kholo ts'ebetsong ea nako e telele ea sistimi. Ka lebaka leo, projeke ea MBE e sebelisa hoo e ka bang Sistimi eohle ea Dynamic Vacuum Pumping.

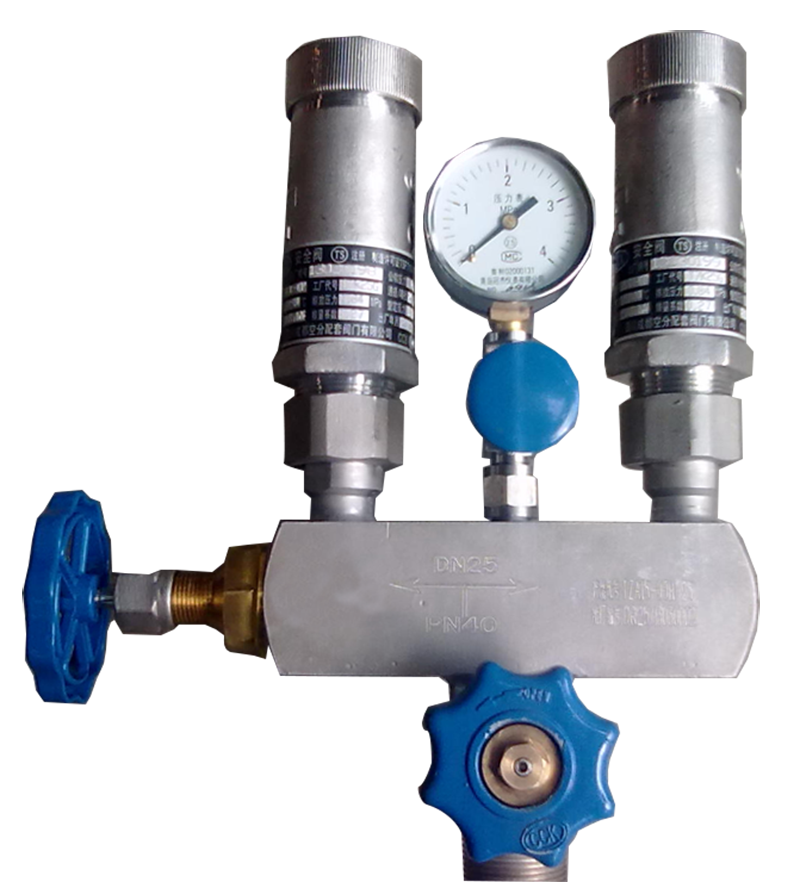

Sistimi ea Phomolo ea Khatello

Sistimi ea ho imolla khatello ea mohala o moholo e sebelisa Sehlopha sa Li-valve tsa Phomolo ea Polokeho. Sehlopha sa Li-valve tsa Phomolo ea Polokeho se sebelisoa e le sistimi ea tšireletso ea Polokeho ha khatello e feteletseng, VI Piping e ke ke ea fetoloa ts'ebelisong e tloaelehileng.

Valve ea Phomolo ea Polokeho ke karolo ea bohlokoa ho netefatsa hore sistimi ea liphaephe ha e na khatello e feteletseng, ts'ebetso e sireletsehileng, kahoo e bohlokoa ts'ebetsong ea liphaephe. Empa valve ea polokeho ho latela molaoana, e tlameha ho romeloa ho ea hlahlojoa selemo se seng le se seng. Ha valve e 'ngoe ea polokeho e sebelisoa 'me e' ngoe e lokisitsoe, ha valve e 'ngoe ea polokeho e tlosoa, valve e 'ngoe ea polokeho e ntse e le tsamaisong ea liphaephe ho netefatsa ts'ebetso e tloaelehileng ea phaephe.

Sehlopha sa Safety Relief Valve se na le Divalve tse pedi tsa DN15 Safety Relief, e nngwe bakeng sa tshebediso le e nngwe bakeng sa ho ema. Tshebetsong e tlwaelehileng, Divalve tse le nngwe feela tsa Safety Relief di hokahantswe le Sistimi ya VI Piping mme di sebetsa ka tsela e tlwaelehileng. Divalve tse ding tsa Safety Relief di kgaotswe phaepheng e ka hare mme di ka nkelwa sebaka neng kapa neng. Divalve tse pedi tsa polokeho di hokahantswe mme di kgaotswe ka boemo ba ho fetola divalve tse ka thoko.

Sehlopha sa Safety Relief Valve se hlomelitsoe ka sekala sa khatello ho hlahloba khatello ea sistimi ea liphaephe neng kapa neng.

Sehlopha sa Safety Relief Valve se fuwa valve e ntshang metsi. E ka sebediswa ho ntsha moya ka hara phaephe ha e hlatswa, mme naetrojene e ka ntshwa ha tsamaiso ya naetrojene e metsi e ntse e sebetsa.

Lisebelisoa tsa HL Cryogenic

HL Cryogenic Equipment e thehiloeng ka 1992 ke lets'oao le amanang le Khamphani ea Lisebelisoa tsa Chengdu Holy Cryogenic Chaena. HL Cryogenic Equipment e ikemiselitse ho rala le ho etsa Sistimi ea Liphaephe tsa Cryogenic e nang le Vacuum e Phahameng le Lisebelisoa tse amanang le eona.

Lefatšeng la kajeno le fetohang ka potlako, ho fana ka theknoloji e tsoetseng pele ha ka nako e ts'oanang ho boloka litšenyehelo bakeng sa bareki ke mosebetsi o boima. Ka lilemo tse 30, Khamphani ea Lisebelisoa tsa Cryogenic ea HL hoo e batlang e le lisebelisoa tsohle tsa cryogenic le indasteri li na le ts'ebeliso e tebileng haholoanyane, li bokelletse boiphihlelo bo bongata le bo tšepahalang, 'me li ntse li hlahloba le ho loanela ho tsamaisana le nts'etsopele ea morao-rao maemong ohle a bophelo, li fa bareki litharollo tse ncha, tse sebetsang le tse sebetsang hantle, li etsa hore bareki ba rona ba qothisane lehlokoa haholoanyane 'marakeng.

For more information, please visit the official website www.hlcryo.com, or email to info@cdholy.com .

Nako ea poso: Phato-25-2021