Mekhoa ea ho pholisa naetrojene e metsi e sebelisoa haholo indastering ea li-semiconductor le chip, ho kenyeletsoa le ts'ebetso ea,

- Theknoloji ea Molecular Beam Epitaxy (MBE)

- Teko ea chip kamora sephutheloana sa COB

Lihlahisoa tse Amanang

EPITAXY EA LIMOLECULAR BEAM

Theknoloji ea Molecular Beam Epitaxy (MBE) e ile ea ntlafatsoa lilemong tsa bo-1950 ho lokisa thepa ea filimi e tšesaane ea semiconductor ho sebelisoa theknoloji ea mouoane oa vacuum. Ka nts'etsopele ea theknoloji ea vacuum e phahameng haholo, ts'ebeliso ea theknoloji e atolositsoe ho ea lefapheng la mahlale a semiconductor.

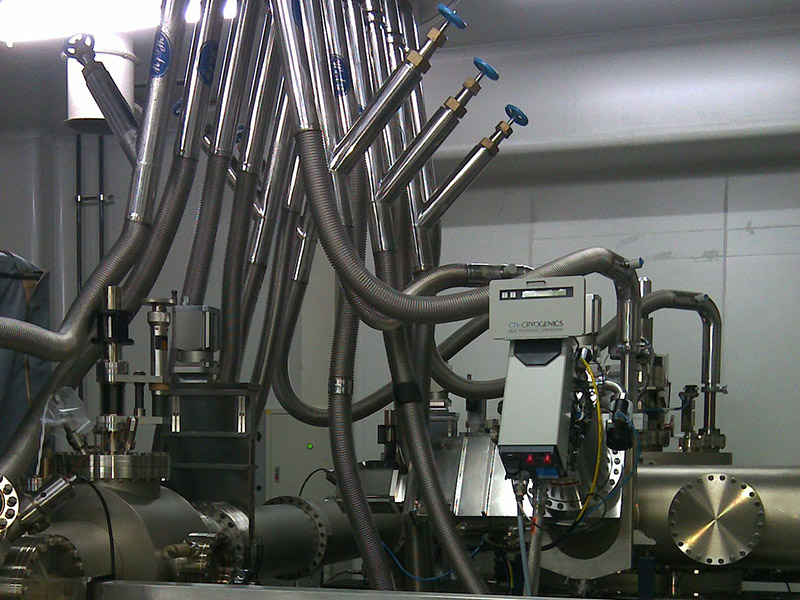

HL e hlokometse tlhoko ea sistimi ea ho pholisa ea naetrojene ea metsi ea MBE, mokokotlo o hlophisitsoeng oa botekgeniki ho nts'etsapele ka katleho sistimi e khethehileng ea ho phunya naetrojene ea metsi ea MBE bakeng sa theknoloji ea MBE le sete e felletseng ea sistimi ea liphaephe tse koahetsoeng ka vacuum, e 'nileng ea sebelisoa likhoebong tse ngata, liunivesithing le litsi tsa lipatlisiso.

Mathata a tloaelehileng a indasteri ea li-semiconductor le li-chip a kenyelletsa,

- Khatello ea Naetrojene e Metsi ho ea Lisebelisoang tsa Terminal (MBE). Thibela Khatello e Feteletseng ho tsoa ho Lisebelisoa tse Senyang Terminal (MBE).

- Taolo ea ho Kena le ho Tsoa ha Metsi a Cryogenic a mangata

- Mocheso oa Naetrojene e Metsi ka har'a Lisebelisoa tsa Terminal

- Palo e Loketseng ea Mesi e Hlahang ea Khase ea Cryogenic

- (Ka boiketsetso) Ho Fetola Mela e Meholo le ea Lekala

- Phetoho ea Khatello (Phokotso) le Botsitso ba VIP

- Ho Hloekisa Litšila Tse ka Bang Teng le Masalla a Leqhoa a tsoang Tankeng

- Nako ea ho Tlatsa ea Lisebelisoa tsa Metsi tsa Terminal

- Ho Pholisa Liphaephe Pele ho Nako

- Khanyetso ea Metsi Tsamaisong ea VIP

- Tahlehelo ea Taolo ea Nitrojene e Metsi Nakong ea Tšebeletso e sa Tsoeleng ea Sistimi

Pipe ea HL e nang le Vacuum Insulated (VIP) e hahiloe ho latela khoutu ea ASME B31.3 Pressure Piping e le tekanyetso. Phihlelo ea boenjiniere le bokhoni ba taolo ea boleng ho netefatsa katleho le katleho ea fektheri ea moreki.

LITHAROLLO

Sesebelisoa sa HL Cryogenic Equipment se fa bareki Sistimi ea Liphaephe tse Kenngoeng ka Vacuum ho fihlela litlhoko le maemo a indasteri ea li-semiconductor le li-chip:

1. Sistimi ea Tsamaiso ea Boleng: Khoutu ea Liphaephe tsa Khatello ea ASME B31.3.

2. Sekarohano sa Mokhahlelo o Ikhethang se nang le Mokero o Mongata oa Liquid le Outlet tse nang le ts'ebetso ea taolo e iketsang se fihlela tlhoko ea ho ntšoa ha khase, naetrojene e metsi e sebelisitsoeng hape le mocheso oa naetrojene e metsi.

3. Moralo o lekaneng le o nakong oa ho ntša mosi o netefatsa hore lisebelisoa tsa terminal li lula li sebetsa ka har'a boleng ba khatello bo entsoeng.

4. Sethibelo sa mokelikeli oa khase se beoa ka har'a phaephe ea VI e otlolohileng qetellong ea phaephe ea VI. Sethibelo sa mokelikeli oa khase se sebelisa molao-motheo oa tiiso ea khase ho thibela mocheso ho tloha pheletsong ea phaephe ea VI ho ea ho Phaephe ea VI, le ho fokotsa tahlehelo ea naetrojene e metsi ka katleho nakong ea ts'ebeletso e sa khaotseng le e sa khaotseng ea sistimi.

5. VI Piping e Laolwang ke Vacuum Insulated Valve (VIV) Series: Ho kenyeletsoa Vacuum Insulated (Pneumatic) Shut-off Valve, Vacuum Insulated Check Valve, Vacuum Insulated Regulating Valve jj. Mefuta e fapaneng ya VIV e ka kopanngwa ka modular ho laola VIP ha ho hlokahala. VIV e kopantswe le VIP prefabrication ho moetsi, ntle le kalafo ya Insulated sebakeng seo. Yuniti ya tiiso ya VIV e ka nkelwa sebaka habonolo. (HL e amohela letshwao la cryogenic valve le kgethilweng ke bareki, ebe e etsa di-valve tse sireletsang vacuum ke HL. Mefuta e meng ya di-valve le di-valve di kanna tsa se kgone ho etswa di-valve tse sireletsang vacuum.)

6. Bohloeki, haeba ho na le litlhoko tse ling bakeng sa bohloeki ba bokaholimo ba tube ea ka hare. Ho khothalletsoa hore bareki ba khethe liphaephe tsa tšepe e sa ruseng tsa BA kapa EP e le liphaephe tsa ka hare tsa VIP ho fokotsa ho tšoloha ha tšepe e sa ruseng.

7. Sefe e Sirelelitsoeng ka Vacuum: Hloekisa litšila tse ka bang teng le masalla a leqhoa ka tankeng.

8. Kamora matsatsi a 'maloa kapa ho koaloa kapa tlhokomelo ho feta, ho hlokahala haholo ho pholile pele ho kenngoa mokelikeli oa cryogenic oa VI Piping le thepa ea terminal, e le ho qoba ho bola ha leqhoa kamora hore mokelikeli oa cryogenic o kene ka ho toba ho VI Piping le thepa ea terminal. Mosebetsi oa pele ho pholile o lokela ho nahanoa moralong. E fana ka tšireletso e betere bakeng sa lisebelisoa tsa terminal le lisebelisoa tsa tšehetso tsa VI Piping tse kang li-valve.

9. E loketse Sistimi ea Liphaephe tse Feto-fetohang le tse sa Fetoheng tsa Vacuum Insulated (Flexible).

10. Sistimi ea Liphaephe tse Insulated ka Vacuum e Matla (e Tenyetsehang): E na le Liphaephe tse Fetohang tsa VI le/kapa Phaephe ea VI, Liphaephe tsa Jumper, Sistimi ea Valve e Insulated ka Vacuum, Li-Phase Separators le Sistimi ea Liphaephe tse Fetohang ka Vacuum (ho kenyeletsoa lipompo tsa vacuum, li-valve tsa solenoid le li-gauge tsa vacuum jj.). Bolelele ba Phaephe e le 'ngoe e Fetohang ea VI bo ka fetoloa ho latela litlhoko tsa mosebelisi.

11. Mefuta e fapaneng ea Khokahano: Mofuta oa Khokahano ea Vacuum Bayonet (VBC) le Khokahano e Welded li ka khethoa. Mofuta oa VBC ha o hloke kalafo e sireletsang sebakeng seo.